DESCRIPTION

The function of the Engineered Discharge Nozzle in a fire extinguishing system is to distribute the Clean Agent in a uniform, pre-determined pattern and concentration. The nozzles are designed to complete the discharge of Clean Agent in 10 seconds or less when installed within the design limitations of the Design Manual and the Flow Calculation computer program. Engineered Discharge Nozzles are available in sizes of 3/8” (10mm) through 2” (50mm). Each nozzle is available in 180 and 360 degree discharge patterns. The Discharge Nozzle size refers to the size of Schedule 40 or 80 steel pipe to which it can be connected. The nozzle discharge orifices are drilled perpendicular to the center line of the threads. The nozzles are mounted to allow the agent to be discharged on a horizontal axis.

Nozzle orifices are available in a wide range of sizes to provide accurate clean agent flow results. All nozzles have been tested for their ability to discharge the clean agent under extreme conditions. Nozzle orifice drilling must be done at the factory only after “As-Built” calculations of the installed piping system(s) have been performed, using the Flow Calculation computer program. The Discharge Nozzle used shall be Factory Mutual (FM) approved and Underwriters Laboratories (UL) listed.

ARCHITECT AND ENGINEERING SPECIFICATIONS

The nozzle used to disperse Clean Agent shall be a Series 80. The nozzle shall be available in 3/8” (10mm) through 2” (50mm) sizes. Each size shall be available in both 180 and 360 degree dispersion patterns. The nozzle used shall have pipe threads that correspond to the nozzle size. All nozzles shall have an orifice size determined by a UL listed and FM approved flow calculation program. All nozzle orifice drilling shall be performed by the manufacturer.

NOZZLE SIZE AND AREA COVERAGE

|

Nozzle Size - 3/8” - 2” (10 - 50 mm) |

||

|

Ceiling Height Range ft. (m) |

Radius “R” Dimensions ft. (m) |

Nozzle Type |

|

1.0 to 16.0 (0.3 to 4.9) |

45.67 (13.92) |

180° |

|

1.0 to 16.0 (0.3 to 4.9) |

29.67 (9.04) |

360° |

|

NOZZLE SIZE |

|

|

(NPT) |

(mm) |

|

3/8” |

10 |

|

1/2” |

15 |

|

3/4” |

20 |

|

1” |

25 |

|

1 1/4” |

32 |

|

1 1/2” |

40 |

|

2” |

50 |

NOTES:

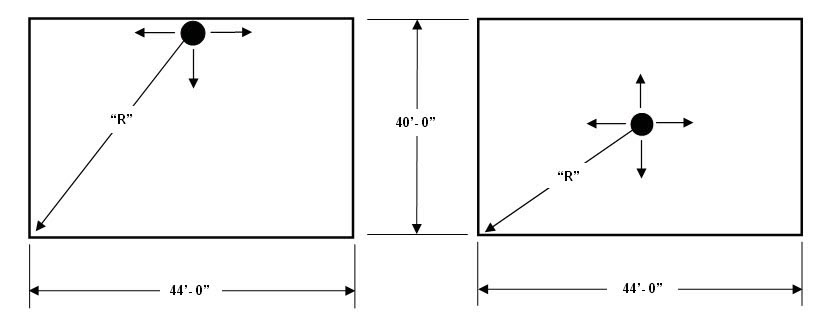

a. The maximum allowable area of coverage includes any area within the radius distance from the nozzle (“R” dimension) to the most extreme wall or corner.

b. Nozzles should be located on center line of hazard area.

c. When working with ceiling heights exceeding the values tabulated above, the hazard volume must be broken down into vertically stacked hazard volumes, with heights less than the maximums shown in the table. It is imperative that unusual applications of this nature be handled by experienced design engineers and, in most cases, operational tests should be performed before the system is put into service.

d. 180 and 360 degree nozzles may be placed a maximum of 1 foot (30.5cm) down from the ceiling, and 180 degree nozzles may be placed a maximum of 1 foot (30.5cm) from the wall. e. Nozzle threading is NPT.

021-44894049-44894059

021-44894049-44894059